Rotary bridge compost tedder

The Rotary Bridge Compost Tedder is an automated system for tedding animal and vegetable waste with additional inclusions.

The machine has two functions: stacking and tedding of the stack.

In the laying mode, the compost is fed from the storage conveyor to the stationary inclined belt conveyor, which in turn feeds the material through another stationary conveyor to the reel reversing conveyor forming the compost pile.

The principle of operation of the machine in tedding mode is that by moving across the buried composting site, the tedder carriage, with its blades mounted on the rotor, mixes and moves the biomass, giving it access to oxygen. Then the process of aerobic fermentation of biomass and its further processing into organic fertilizer starts. The agitator gradually mixes and moves the compost forward on the compost site from the stack formation point to the outermost boundary. By the time the compost reaches the outermost boundary of the compost pad, the composting process is completed and the finished product is loaded onto a vehicle, delivered to customers for use in agriculture. This usually takes about a month. During this time, the compost is regularly sprayed with a special water-based bioactive compound from a storage tank installed on the tedder via a system of nozzles positioned on the tedder.

A rotary bridge tedder is installed on an enclosed composting site.

The machine is controlled from a local control panel located in a separate enclosed room of the building.

The construction of the tedder is designed in accordance with modern engineering trends and ensures safe and easy operation. It is easy to maintain and repair.

- metal construction;

- bogie;

- the movement mechanism of the machine;

- electrical set;

- control panel;

- electrical equipment cabinets;

- control system;

- material spraying system.

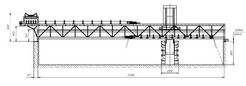

The machine's steel structure is supported by four travel wheels of the machine's travel gear, which are driven by a travel gear consisting of four separate drives.

The trolley travels on rails fixed to the upper chords of the steelwork girders.

The trolley carries the rotor, the trolley travel mechanism, the rotor lifting mechanism and the rotor rotation mechanism.

A spraying system is installed on the trolley to spray the material during tedding. Liquid is sprayed in the immediate vicinity of the material as it is tedded.

The machine is equipped with a skew alignment function, which is used to correct misalignment of the machine's steel structure when the machine is in motion.

LED lights are used to illuminate the working area beneath the steel structure of the machine, and are located within easy reach for maintenance and repair work.

- electric drive which does not require the use of expensive liquid fuel;

- The design of all units of the machine allows replacing defective equipment without removing the metal structures and similar large components, which increases the maintainability of the machine;

- The tedding process is automated as much as possible, the human factor is minimised;

- the design of the machine ensures the safety of the operating personnel during installation, operation, maintenance and repair;

- The machine has no restrictions on the combination of working movements allowed by the operating conditions.

The machine has two functions: stacking and tedding of the stack.

In the laying mode, the compost is fed from the storage conveyor to the stationary inclined belt conveyor, which in turn feeds the material through another stationary conveyor to the reel reversing conveyor forming the compost pile.

The principle of operation of the machine in tedding mode is that by moving across the buried composting site, the tedder carriage, with its blades mounted on the rotor, mixes and moves the biomass, giving it access to oxygen. Then the process of aerobic fermentation of biomass and its further processing into organic fertilizer starts. The agitator gradually mixes and moves the compost forward on the compost site from the stack formation point to the outermost boundary. By the time the compost reaches the outermost boundary of the compost pad, the composting process is completed and the finished product is loaded onto a vehicle, delivered to customers for use in agriculture. This usually takes about a month. During this time, the compost is regularly sprayed with a special water-based bioactive compound from a storage tank installed on the tedder via a system of nozzles positioned on the tedder.

A rotary bridge tedder is installed on an enclosed composting site.

The machine is controlled from a local control panel located in a separate enclosed room of the building.

The construction of the tedder is designed in accordance with modern engineering trends and ensures safe and easy operation. It is easy to maintain and repair.

The machine consists of the following main parts:

- metal construction;

- bogie;

- the movement mechanism of the machine;

- electrical set;

- control panel;

- electrical equipment cabinets;

- control system;

- material spraying system.

The machine's steel structure is supported by four travel wheels of the machine's travel gear, which are driven by a travel gear consisting of four separate drives.

The trolley travels on rails fixed to the upper chords of the steelwork girders.

The trolley carries the rotor, the trolley travel mechanism, the rotor lifting mechanism and the rotor rotation mechanism.

A spraying system is installed on the trolley to spray the material during tedding. Liquid is sprayed in the immediate vicinity of the material as it is tedded.

The machine is equipped with a skew alignment function, which is used to correct misalignment of the machine's steel structure when the machine is in motion.

LED lights are used to illuminate the working area beneath the steel structure of the machine, and are located within easy reach for maintenance and repair work.

The main advantages of using an automatic rotary compost tedder are:

- electric drive which does not require the use of expensive liquid fuel;

- The design of all units of the machine allows replacing defective equipment without removing the metal structures and similar large components, which increases the maintainability of the machine;

- The tedding process is automated as much as possible, the human factor is minimised;

- the design of the machine ensures the safety of the operating personnel during installation, operation, maintenance and repair;

- The machine has no restrictions on the combination of working movements allowed by the operating conditions.

Back to the list